Views: 0 Author: Site Editor Publish Time: 2025-08-13 Origin: Site

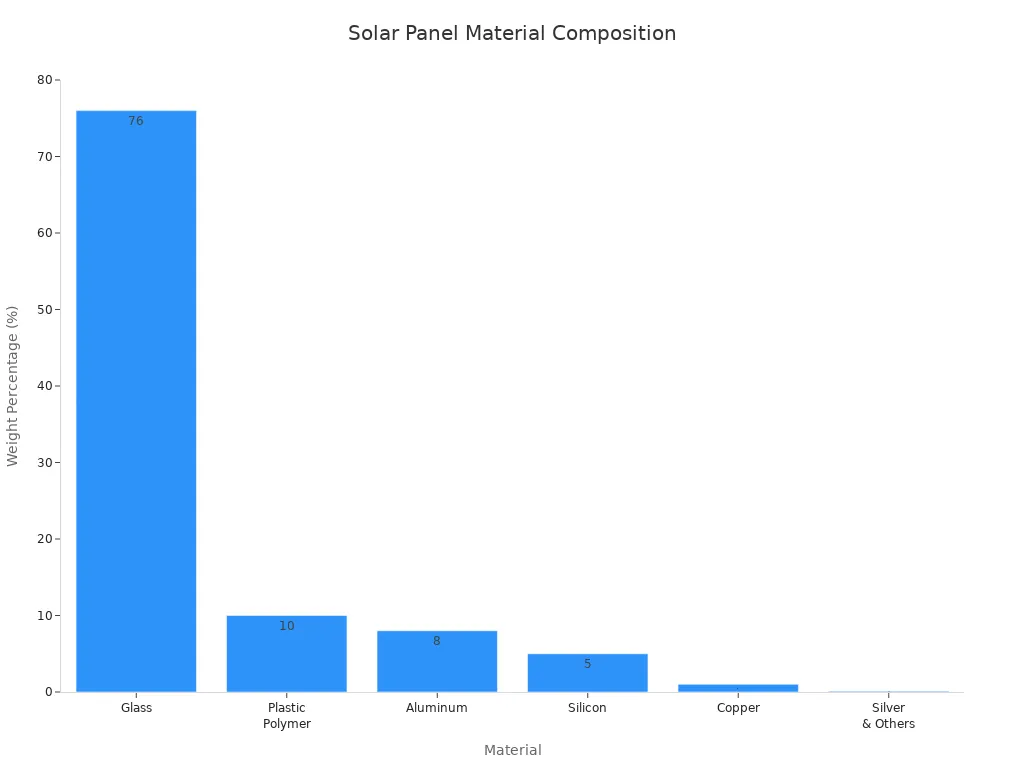

Material | Typical Weight Percentage |

|---|---|

Glass | ~76% |

Plastic Polymer | ~10% |

Aluminum | ~8% |

Silicon | ~5% |

Copper | ~1% |

Silver & Others | <0.1% |

These components impact the environment through mining, emissions, and recycling challenges.

Silicon is the core material in solar panels, converting sunlight into electricity efficiently and reliably.

Tempered glass protects solar cells from damage and weather while allowing sunlight to pass through effectively.

Aluminum frames and mounting systems provide strong, lightweight, and corrosion-resistant support for solar panels.

Polymers like EVA and PVF protect solar cells from moisture, UV rays, and mechanical stress, extending panel lifespan.

Copper and silver enable efficient electrical flow, boosting solar panel performance despite their small amounts.

Recycling solar panel materials like glass, aluminum, and metals reduces environmental impact and supports sustainability.

Mounting systems made from corrosion-resistant metals keep panels secure and properly angled for maximum energy output.

Choosing high-quality materials and proper installation ensures solar panels last 25 years or more with reliable performance.

Silicon stands as the foundation of most solar panels. Manufacturers rely on silicon for its unique semiconductor properties, which make it ideal for converting sunlight into electricity. Silicon solar cells form the core of photovoltaic cells, enabling solar panels to generate electricity efficiently.

Solar panels use several types of silicon, each with distinct characteristics. The two most common forms are monocrystalline and polycrystalline silicon. Thin-film silicon also appears in some specialized applications.

Monocrystalline silicon solar cells feature a single, continuous crystal structure. These cells appear with rounded corners and a uniform dark color. The manufacturing process for monocrystalline silicon requires more energy, resulting in higher costs. However, these solar cells deliver the highest efficiency and longest lifespan among silicon-based photovoltaic cells. Monocrystalline panels offer better aesthetics and occupy less space due to superior area utilization.

Polycrystalline solar cells consist of multiple silicon crystals fused together. These cells display a blue, patterned surface resembling ice flowers and have square corners. The production of polycrystalline silicon consumes less energy, making it more environmentally friendly and cost-effective. Polycrystalline panels provide slightly lower efficiency and shorter lifespan compared to monocrystalline panels. They require more space for the same power output but dominate the market due to their affordability.

Silicon Type | Appearance | Manufacturing Process | Efficiency & Performance | Advantages & Disadvantages | Applications & Notes |

|---|---|---|---|---|---|

Monocrystalline Si | Rounded corners, uniform color | Energy-intensive | Highest efficiency, best area utilization | High power, fragile, higher cost, less effective in high-temp/low-light | Premium residential and commercial panels |

Polycrystalline Si | Square corners, patterned surface | Less energy-intensive | Slightly lower efficiency, no area loss | Cheaper, eco-friendly, lower efficiency and lifespan | Widely used, cost-effective |

Amorphous Si | Smooth, mirror-like surface | Thin-film deposition | Lower power, good high-temp/low-light performance | Flexible, low output, low degradation, aesthetically pleasing | Specialized applications, shading tolerance |

Silicon solar cells drive the photovoltaic effect, which allows solar panels to generate electricity. The process involves several steps:

Silicon absorbs photons from sunlight.

The energy excites electrons within the silicon atoms.

Freed electrons move, creating an electric current.

Solar cells contain two layers of silicon, each doped with different elements to form an electric field.

This electric field directs the flow of electrons, producing direct current (DC).

An inverter converts DC into alternating current (AC) for practical use.

Solar panels rely on crystalline-silicon solar technology for reliable and efficient electricity production. The structure of silicon solar cells ensures consistent performance across various environmental conditions.

The efficiency of silicon-based solar panels determines how much sunlight they convert into usable electricity. Monocrystalline solar cells achieve commercial efficiencies between 20% and 25%, with lifespans reaching up to 40 years. Polycrystalline solar cells typically reach 18% to 21% efficiency and last 25 to 30 years. Thin-film silicon panels offer lower efficiency, around 17% to 19%, but perform well in high temperatures and low-light environments.

Photovoltaic Material / Technology | Efficiency Range (Commercial) | Efficiency Range (Laboratory) | Notes |

|---|---|---|---|

Silicon-based commercial panels | 15% - 22% | 25% - 30% | Includes monocrystalline and heterojunction technologies; dominant in market |

Cadmium Telluride (CdTe) thin-film panels | ~18% | N/A | Lower efficiency but better performance in hot climates and low light |

Multi-junction cells | N/A | >29% up to >40% (concentrated) | Combine different semiconductors; high lab efficiencies but limited commercial use |

Perovskite-silicon tandem cells | N/A | >29% | Emerging technology with promising high lab efficiencies |

Solar panels using silicon solar cells continue to dominate the market due to their balance of efficiency, durability, and cost. Advances in photovoltaic technology, such as heterojunction and tandem cells, promise even greater performance in the future.

Glass serves as the primary protective layer for solar panels. Manufacturers most commonly use tempered soda-lime glass, which combines silicon dioxide, sodium oxide, and calcium oxide. This composition balances cost, durability, and light transmission. Tempered glass is about four times stronger than standard plate glass. If broken, it shatters into small, less hazardous pieces, reducing injury risk. The glass shields the delicate photovoltaic cells from moisture, dirt, and oxygen, preventing damage and oxidation. It also acts as an insulator, stopping electrical conduction and protecting users from electric shock.

Tip: Tempered glass provides mechanical strength and fire resistance, making it ideal for rooftop solar installations.

Solar glass must transmit sunlight efficiently while withstanding harsh weather. The protective layer resists impacts from hail, wind, and debris. In regions with frequent storms, this durability ensures that panels continue to operate safely and reliably.

Type of Glass | Key Properties and Usage in Solar Panels |

|---|---|

Tempered Soda-Lime | Most common; high durability; shatters safely; can be low iron for better light transmission. |

Plate Glass | Less durable; breaks into sharp pieces; used in thin-film panels. |

Borosilicate Glass | Higher cost; better heat resistance and transmission. |

Lead Crystal Glass | Highest clarity; most resistant to heat expansion; expensive. |

Anti-reflective coatings play a vital role in boosting the efficiency of solar panels. These coatings reduce the reflection of sunlight, allowing more solar energy to reach the photovoltaic cells. Manufacturers use materials like silica nanoparticles and aluminum oxide for their optical properties and durability. The coating’s low refractive index and optimized thickness minimize light loss across different wavelengths and angles.

Panels with anti-reflective glass can increase annual energy production by 6% to 12%. This improvement is most noticeable when the sun is at an angle, such as early morning or late afternoon. By reducing reflection losses, the coating extends the operational hours of solar panels and increases overall power output. Fewer panels are needed for the same power rating, which leads to cost savings and more efficient use of space.

Durability is a key factor in the long-term performance of solar panels. Tempered or semi-tempered glass, typically 2 mm to 2.5 mm thick, provides superior mechanical strength. This glass resists impacts from wind, snow, hail, and debris. It also withstands UV degradation, moisture ingress, and temperature fluctuations, which extends the lifespan of panels.

Manufacturers use encapsulants like polyolefin elastomer (POE) or ethylene-vinyl acetate (EVA) to ensure strong adhesion and reduce microcracks from thermal cycling and mechanical stress. Dual-glass structures further reduce potential-induced degradation, especially in high-humidity and high-voltage environments. Protective coatings minimize dust accumulation and surface wear, improving energy yield.

Glass-glass modules show enhanced resistance to moisture and harsh weather, making them suitable for extreme climates. The robust design leads to low degradation rates, around 0.4% per year, and operational lifespans exceeding 30 years. Routine maintenance, such as cleaning and inspections, helps maintain durability and performance.

Aluminum plays a vital role in the structure and installation of solar panels. Manufacturers use aluminum frames to protect the edges and corners of each panel. These frames prevent damage from impacts and reduce the risk of electrical malfunctions. The lightweight nature of aluminum allows for easier handling during installation, while its strength ensures panels remain secure even in harsh weather.

Solar panel mounting systems also rely on aluminum rails and brackets. These components provide a sturdy framework that supports and aligns panels on rooftops or ground mounts. Aluminum rails withstand wind, rain, and snow, keeping panels firmly in place. Installers benefit from the material’s low weight, which reduces labor and transportation costs. The design of aluminum mounting systems, such as HINA’s Aluminum Rail Solution for trapezoidal metal roofs, allows for quick and efficient installation on various roof types. This adaptability makes aluminum the preferred choice for both residential and commercial solar projects.

Aluminum frames and rails not only enhance the structural integrity of solar panels but also contribute to a clean, modern appearance for solar installations.

Aluminum’s natural corrosion resistance stands out as one of its most important properties for solar applications. When exposed to air, aluminum forms a thin oxide layer that protects it from further oxidation. This feature ensures long-term durability, especially in outdoor environments where moisture, UV radiation, and temperature changes are common.

Aluminum’s protective oxide layer extends the operational life of solar panels, even in coastal or high-humidity regions.

Compared to other metals, aluminum offers superior resistance to corrosion, reducing the need for frequent maintenance.

Manufacturers often apply additional coatings, such as anodizing or powder coating, to further enhance corrosion resistance.

Aluminum extrusions used in frames and mounting racks endure decades of exposure without degrading, supporting the reliability of solar energy systems.

These qualities make aluminum an ideal material for solar panel frames and mounting systems, ensuring that installations remain safe and effective over time.

Sustainability remains a key consideration in solar panel manufacturing. Aluminum frames account for about 8% to 10% of a solar panel’s total weight. Many manufacturers now use recycled aluminum, which maintains the same strength and durability as new material. This practice reduces the carbon footprint of solar panels by up to 67%, supporting environmental goals and circular economy principles.

Recycling aluminum requires only about 5% of the energy needed to produce new aluminum from raw ore. This significant energy saving lowers greenhouse gas emissions and minimizes the environmental impact of solar panel production. At the end of a solar panel’s life, aluminum frames and mounting components can be easily separated and recycled, further enhancing the sustainability of solar energy systems.

The use of recycled aluminum in solar panels not only conserves resources but also supports a cleaner, greener future for renewable energy.

Polymers play a crucial role in the construction and performance of solar panels. These synthetic materials protect sensitive components, enhance durability, and ensure long-term reliability. Manufacturers select specific polymers for encapsulation and backsheet layers, each serving unique functions within the solar module.

Encapsulation polymers form a protective layer around the solar cells. This layer bonds the cells to the glass front and the backsheet, preventing delamination and shielding the cells from mechanical and environmental harm. The most common encapsulant is ethylene-vinyl acetate (EVA), valued for its optical clarity, flexibility, and strong adhesion. Polyolefin (POE) and other alternatives like PVB, ionomer, and silicone also appear in some modules.

Polymer Type | Used For | Main Functions |

|---|---|---|

Ethylene-vinyl acetate (EVA) | Encapsulation | Mechanical cushioning, electrical insulation, moisture barrier, optical transparency, adhesion, thermal insulation, UV resistance |

Polyolefin (POE) | Encapsulation | Similar protective and bonding functions as EVA |

PVB, ionomer, silicone | Encapsulation | Alternative encapsulants with protective and adhesive properties |

EVA and POE encapsulants secure the solar cells, absorb mechanical shocks, and block moisture. Their transparency allows maximum sunlight to reach the cells, supporting high energy output. These polymers also resist UV radiation, which helps prevent yellowing and degradation over time.

Encapsulation polymers act as the first line of defense, keeping solar cells safe from water, dust, and temperature swings.

The backsheet forms the outermost layer on the rear side of the solar panel. This layer provides environmental protection, electrical insulation, and mechanical support. Manufacturers use several types of polymers for backsheets, often in multilayer structures to balance performance and cost.

Polymer Type | Application | Main Functions |

|---|---|---|

Polyvinyl Fluoride (PVF) | Backsheet | Environmental barrier, moisture ingress protection, UV resistance, electrical insulation, mechanical support |

Polyvinylidene Fluoride (PVDF) | Backsheet | High mechanical strength, UV resistance, chemical stability, moisture barrier |

Polyester (PET) | Backsheet | Provides insulation, mechanical support, and forms part of multilayer backsheet structures |

PVF and PVDF offer excellent weather resistance and UV protection, making them ideal for harsh outdoor environments. PET provides mechanical strength and insulation, often serving as the core layer in composite backsheets. These multilayer designs help prevent moisture ingress, electrical faults, and physical damage.

Backsheets ensure the safe operation of solar panels by blocking moisture, dust, and harmful UV rays.

Polymers directly influence the lifespan and reliability of solar panels. Advanced encapsulants and backsheet materials maintain their integrity despite years of exposure to sunlight, rain, and temperature changes. Modern polymer sealants exhibit superior flexibility and strength, allowing them to withstand thermal cycling and structural movement without cracking or losing adhesion.

Manufacturers use multilayer polymer encapsulation to shield sensitive components from moisture and UV damage. This protection reduces the risk of corrosion and electrical failure, extending the operational life of the panel. Innovations in polymer chemistry have also improved the stability of organic photovoltaic materials, making them more durable and suitable for long-term use.

Solar panels with high-quality polymer layers can operate reliably for 25 years or more. These materials help maintain performance, reduce maintenance needs, and ensure that solar energy systems deliver consistent power throughout their service life.

Solar panels rely on a range of metals and minerals to achieve efficient energy conversion and long-term durability. These materials play critical roles in electrical conductivity, structural support, and overall panel performance. Understanding the presence and function of minerals in solar panels helps explain how solar cells generate electricity and why certain metals remain essential for modern solar technology.

Copper stands out as one of the most important minerals in solar panels. Manufacturers use copper primarily for wiring and busbars, which connect solar cells and transport electricity throughout the panel. Copper’s high electrical conductivity ensures minimal energy loss during transmission. This property makes copper indispensable for efficient solar energy generation.

Copper wiring links individual solar cells, forming a network that collects and delivers power.

The metal also helps dissipate heat, protecting panels from thermal damage.

Copper accounts for about 1% of the total weight in a typical solar panel.

Copper’s role extends to solar batteries, where it supports reliable energy storage and transfer. The widespread use of copper highlights its significance among common minerals in solar panels.

Silver plays a vital role in the electrical performance of solar panels. As a noble metal, silver offers exceptional conductivity, reflectivity, and resistance to corrosion. Manufacturers apply silver in conductive paste on the front surface of solar cells, busbars, and back contacts. These components collect and transfer electrical current with minimal energy loss.

Silver’s superior conductivity boosts the efficiency of silicon solar cells. Although the amount of silver in panels remains small, its impact on performance is substantial. The high cost of silver drives ongoing research to reduce its usage, but demand continues to grow as the solar industry expands.

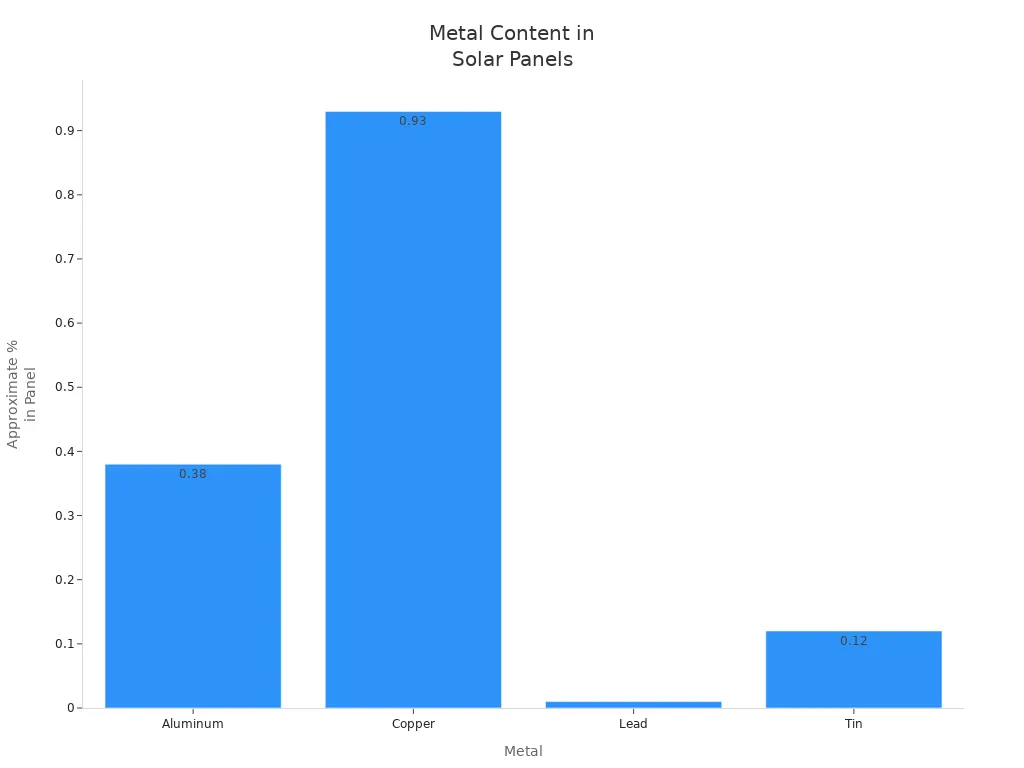

Metal | Approximate % in Monocrystalline Solar Panel | Specific Role in Electrical Conductivity and Solar Panel Functionality |

|---|---|---|

Copper | 0.93% | Wiring between solar cells; efficient electricity flow and heat dissipation |

Silver | Trace amounts | Conductive paste, busbars, back contacts; efficient current collection and transfer |

Silver’s unique properties make it irreplaceable for high-performance solar panels, even as manufacturers seek alternatives.

Beyond copper and silver, several other minerals in solar panels contribute to their structure and function. Tin, lead, and zinc appear in small quantities but serve important roles.

Tin combines with lead to form solder, connecting solar cells and electrical components. Tin oxide also acts as a transparent conductive layer, improving panel efficiency.

Lead, though used less frequently due to environmental concerns, remains present in soldering alloys. Lead’s flexibility and low melting point make it suitable for connecting delicate parts.

Zinc enhances energy conversion efficiency in solar panels. Zinc’s presence supports better performance and reliability.

Mineral | Role in Solar Panels or Batteries | Significance |

|---|---|---|

Tin | Soldering, transparent conductive layer | Improves connectivity and efficiency |

Lead | Soldering alloy, battery plates | Supports connections and energy storage |

Zinc | Efficiency enhancement | Boosts solar energy generation |

The minerals in solar panels and minerals in solar batteries originate from mining operations worldwide. Where are the minerals in solar panels found? Most come from regions rich in metal ores, such as South America, Africa, and Asia. Where are the minerals in solar panels found for tin, lead, and zinc? These minerals often come from specialized mines and recycled materials.

The combination of copper, silver, tin, lead, and zinc ensures that solar panels deliver reliable power and withstand environmental challenges. The careful selection and integration of minerals in solar panels and minerals in solar batteries remain crucial for advancing solar technology.

Solar panels materials appear in distinct proportions, each serving a unique function within the system. The following table displays the typical weight percentage of major components found in standard solar panels:

Material | Approximate Percentage (%) |

|---|---|

Glass | 76 |

Polymers | 10 |

Aluminum | 8 |

Silicon | 5 |

Copper | 1 |

Silver & Others | <0.1 |

Glass forms the largest portion, acting as the protective layer. Polymers encapsulate and insulate the cells. Aluminum provides structural support. Silicon enables energy conversion. Copper and trace minerals ensure electrical conductivity.

Each material in solar panels plays a critical role in performance and durability. Glass shields the sensitive components from weather and impact. Polymers, such as encapsulants and backsheets, protect against moisture and UV radiation. Aluminum frames and mounting rails maintain the panel’s shape and stability. Silicon, as the core semiconductor, converts sunlight into electricity. Copper wires and busbars transport electrical current efficiently. Silver, though present in small amounts, boosts conductivity and panel efficiency.

The synergy of these materials allows solar panels to operate reliably for decades, even in harsh environments.

Solar panels materials must balance strength, efficiency, and longevity. Manufacturers select each component to optimize energy output and minimize maintenance.

Several factors influence the variation in material composition among different types of solar panels:

Manufacturers choose different semiconductor materials, such as monocrystalline silicon, polycrystalline silicon, amorphous silicon, cadmium telluride (CdTe), or copper indium gallium selenide (CIGS). These choices affect efficiency, cost, and environmental impact.

The method of doping silicon (N-type or P-type) changes electrical performance and stability.

Backsheet materials vary, including fluorine-based films or PVDF, to enhance durability and UV resistance.

The use of back glass provides additional moisture barriers and fire resistance, improving panel longevity.

Aluminum alloys in frames offer structural support and protection.

Manufacturing processes differ. Monocrystalline panels use the Czochralski method, while polycrystalline panels rely on a cooling process that creates multiple crystals. Thin-film panels deposit non-crystalline silicon or compounds on glass or plastic, affecting flexibility and efficiency.

These factors determine the exact mix of solar panels materials in each product. The selection of components depends on desired panel performance, installation environment, and cost considerations.

Manufacturers continually refine material choices to improve solar panel efficiency, durability, and sustainability.

Solar panels offer clean energy, but their materials and production processes create environmental considerations. Understanding these impacts helps guide responsible choices in solar panel manufacturing and use.

Most primary materials in solar panels, such as glass, aluminum, silicon, and copper, are highly recyclable. Recycling processes recover valuable resources and reduce landfill waste.

Mechanical recycling starts with removing the aluminum frame and junction box. Workers then separate the glass from silicon cells, recovering over 80% of the materials.

Chemical and thermal recycling use heat or chemicals to separate and purify materials. These methods can achieve up to 95% recovery but require specialized facilities.

Silicon solar cells can be melted and repurposed, though this process needs advanced recycling techniques.

Thin-film panels, like those containing cadmium telluride, undergo different recycling steps to recover semiconductor materials.

The recycling process typically involves three main steps: disassembly, separation, and purification of materials such as glass, aluminum, copper, and silicon.

Recycling solar panels reduces environmental risks and supports a circular economy, but challenges remain. Tightly bonded materials and higher recycling costs compared to landfill disposal slow adoption. Advances in technology and growing recycling programs continue to improve feasibility.

Sustainability in solar panel manufacturing depends on responsible sourcing, efficient production, and adherence to environmental standards. Many organizations and governments promote sustainable practices through certifications and regulations.

Certification/Standard | Focus Area | Description |

|---|---|---|

Certisolis | Life Cycle Assessment | Evaluates environmental impact throughout the panel's life. |

Environmental Product Declaration (EPD) | Environmental Impact | Provides transparent data on environmental effects. |

EPEAT | Ecolabel | Recognizes environmentally preferable solar panels. |

ISO 14001 | Environmental Management | Focuses on environmental management systems. |

RoHS Compliance | Hazardous Substances | Restricts hazardous materials in manufacturing. |

Manufacturers follow these standards to reduce emissions, manage waste, and ensure product safety. Using recycled materials, improving energy efficiency, and minimizing hazardous substances all support sustainability goals.

Solar panel manufacturing faces several environmental challenges. Extracting raw materials like silicon, silver, and aluminum can cause habitat destruction, soil erosion, and water pollution. Production processes use large amounts of energy and water, leading to greenhouse gas emissions and resource strain.

High energy consumption, especially for monocrystalline panels, increases the carbon footprint.

Manufacturing facilities may generate air pollution and require significant water for cooling.

Some panels use hazardous chemicals and heavy metals, which need careful handling to prevent contamination.

End-of-life disposal and recycling demand special attention to avoid environmental risks.

Large-scale solar projects can disrupt local habitats and water resources.

Addressing these challenges requires ethical supply chains, decarbonized production, and improved recycling. U.S. laws and global initiatives encourage recycling and responsible manufacturing to balance the benefits of solar energy with environmental protection.

Mounting systems play a vital role in what solar panels made of, ensuring that every installation remains secure, efficient, and long-lasting. The choice of mounting materials directly affects the durability and safety of solar energy systems.

Manufacturers select specific materials for mounting systems based on their strength, resistance to corrosion, and ease of use. The most common materials include:

Aluminum: Lightweight, corrosion-resistant, and easy to install. Aluminum is ideal for rooftop systems and supports the overall structure without adding excessive weight.

Stainless steel: Offers superior durability and corrosion resistance, especially in harsh or coastal environments.

Zinc Aluminum Magnesium alloys: Provide exceptional corrosion resistance, making them suitable for highly corrosive locations.

Galvanized steel: Used for ground mounts where extra strength is needed.

Material selection depends on environmental factors such as wind speed, snow load, and exposure to salt or chemicals. These materials ensure that solar panels made of robust components remain stable and maintenance-friendly for decades.

Tip: HINA's Aluminum Rail Solution for trapezoidal metal roofs uses anodized aluminum and stainless steel fasteners, combining strength with excellent corrosion resistance for both residential and commercial projects.

Mounting systems form the backbone of every solar installation. They anchor the panels securely to rooftops or ground structures, maintaining the correct tilt and orientation for maximum sunlight exposure. Proper mounting prevents movement during storms and protects the panels from wind uplift or snow accumulation.

Installers benefit from lightweight aluminum rails, which reduce labor and speed up the process. Stainless steel fasteners add extra security, especially in areas with high humidity or salt exposure. Systems like HINA's Aluminum Rail Solution simplify installation by allowing for flexible panel layouts and easy adjustment of tilt angles. This adaptability ensures that solar panels made of advanced materials can be installed efficiently on a wide range of roof types.

The durability of mounting systems is essential for the long-term performance of solar panels made of high-quality materials. Industry standards require the use of corrosion-resistant metals such as anodized 6005-T5 aluminum and SUS304 stainless steel fasteners. These components withstand wind, snow, and temperature changes, preventing mechanical failures and extending the system's lifespan.

Material Property | Aluminum | Steel |

|---|---|---|

Weight | Lightweight, reduces stress on roof | Heavier, requires stronger support |

Corrosion Resistance | Excellent due to protective oxide layer | Prone to rust unless galvanized or coated |

Strength | Good strength, sufficient for rooftop | Superior strength, ideal for ground mounts |

Installation Ease | Easier and faster to install | Requires heavier equipment and more labor |

Maintenance | Minimal upkeep due to corrosion resistance | Needs regular inspection and coating repair |

Environmental Suitability | Ideal for corrosive environments (coastal) | Suitable for high load and snow/wind areas with protection |

Compliance | Meets building codes when designed properly | Meets building codes with proper treatment |

Mounting systems must comply with certifications such as UL and TÜV, which confirm their ability to withstand site-specific wind and snow loads. High-quality mounting materials, protective coatings, and proper installation practices ensure that solar panels made of these systems remain secure and productive for over 25 years. Innovations in sustainable materials, such as recycled aluminum, further reduce environmental impact while maintaining durability.

Solar panels materials each serve a unique purpose, from silicon’s energy conversion to glass’s protection and aluminum’s structural support. The table below highlights how these components contribute to performance and durability:

Component | Function(s) | Contribution to Performance & Durability |

|---|---|---|

Frames | Structural support, mounting | Corrosion resistance, longevity |

Glass | Protection, light transmission | Efficiency, mechanical strength |

Encapsulants | Moisture barrier, cell protection | UV resistance, cell integrity |

Backsheets | Insulation, environmental protection | Electrical safety, lifespan |

Mounting systems ensure panels withstand weather and maintain optimal positioning, supporting long-term reliability. As recycling technology advances, up to 95% of materials can be recovered, reducing the environmental footprint. The industry continues to innovate with sustainable materials and improved recyclability.

Silicon serves as the core material in most solar panels. It converts sunlight into electricity through the photovoltaic effect. Manufacturers choose silicon for its efficiency, durability, and proven performance in energy generation.

Tempered glass protects solar cells from weather, impacts, and moisture. It provides strength and safety. The glass also allows sunlight to pass through efficiently, supporting high energy output.

Aluminum makes up about 8% of a standard solar panel’s weight. It forms the frame and mounting rails, providing structural support and corrosion resistance for long-term durability.

Yes, most metals in solar panels, including aluminum, copper, and steel, are recyclable. Recycling these materials reduces waste and supports a circular economy in the solar industry.

Manufacturers use polymers such as ethylene-vinyl acetate (EVA) for encapsulation and polyvinyl fluoride (PVF) or polyester (PET) for backsheets. These polymers protect cells from moisture, UV rays, and mechanical stress.

Mounting systems ensure panels stay secure and maintain the correct angle for sunlight exposure. High-quality materials like anodized aluminum and stainless steel prevent corrosion and extend system lifespan.

Solar panels reduce carbon emissions by generating clean energy. However, mining and manufacturing materials can cause environmental challenges. Recycling and sustainable sourcing help minimize negative impacts.

Yes, solar panels use durable materials such as tempered glass, aluminum, and corrosion-resistant fasteners. These components help panels resist wind, snow, hail, and temperature changes, ensuring reliable performance.